New Fire-rated Certification in April,2021

New Fire rated Certification in April,2021

Test procedure

The ambient temperature at the beginning of the test was 22 ºC.

The furnace temperature was measured by means of nine thermocouples distributed evenly in the furnace, with their measuring junctions 100 mm ± 10 mm from the exposed surface of the specimen.

The furnace was controlled so that the mean of the nine thermocouple readings followed as closely as possible the time/temperature relationship specified in Clause 3.1 of BS 476-20:1987.

After the first five minutes of the test, the furnace pressure was maintained at 0±2 Pa at 1,000 mm from the notional floor level.

Thermocouples were provided to monitor the unexposed surface of the floor assembly and the output of all instrumentation was recorded at no less than 1 minute intervals. The locations and reference numbers of the various unexposed surface and internal thermocouples are shown in Figure 1.

Test data and information

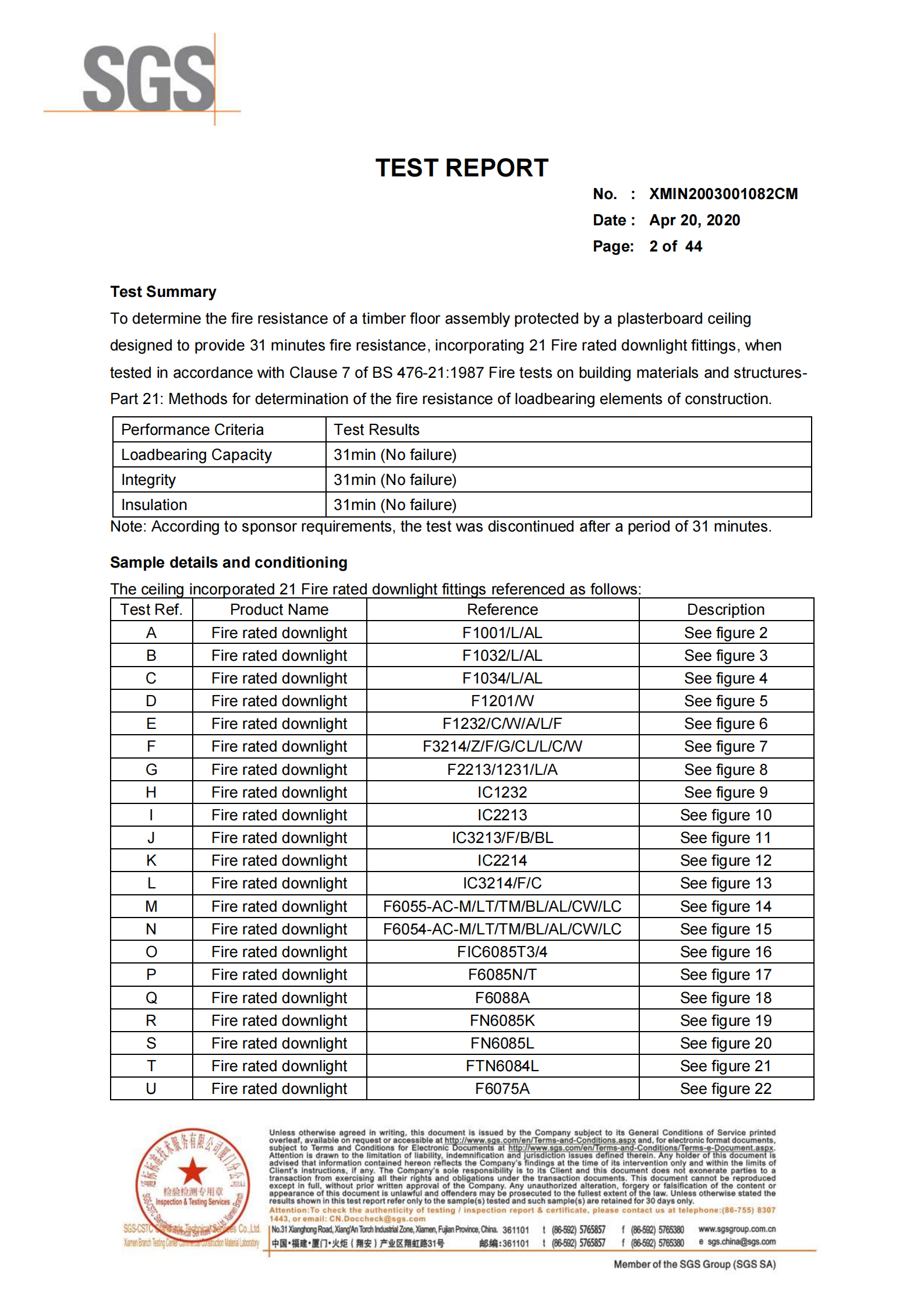

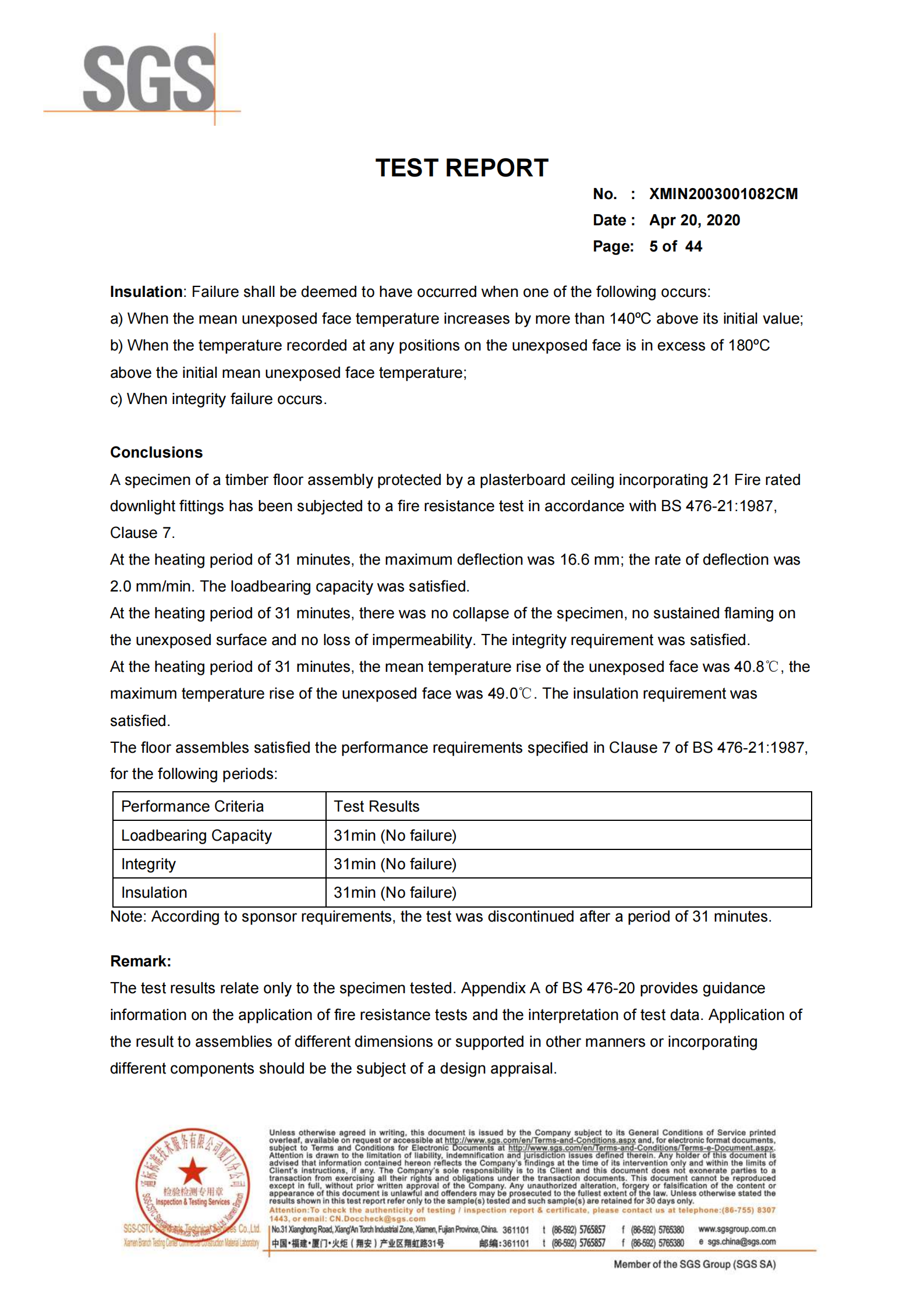

Details of the specimen structure are shown in Figure 1 to 22. The photographs of the Fire rated downlights are shown in Photo 1 to 42.

Photographs of the test are shown in Photos 43 to 50. A summary of the observations made on the general behavior of the specimen is given in Appendix 3.

The mean furnace temperature records are shown in Appendix 4, and the actual time-temperature curve of furnace in relation to the specified time-temperature curve is shown in Figure 23.

The unexposed surface temperature records are shown in Appendix 5, and the individual temperatures recorded adjacent to the spotlight fittings at mid-height of the cavity are shown in Appendix 6. The unexposed surface maximum and mean temperature curve are shown in Figure 24.